Cold Chamber Die Casting

Why Choose

Cold Chamber Die Casting?Cold chamber die casting is the smart choice for projects that demand:- Aluminum expertise

- High quantities

- Parts large in size

- Intricacy and scale

What Is Cold Chamber Die Casting?

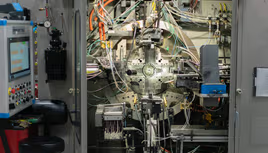

Cold chamber die casting excels at crafting intricate and sizable components. Unlike other die casting methods, it utilizes a separate furnace to melt high-melting-point metals like aluminum. This separation allows for precise control over the metal during injection, resulting in complex shapes with exceptional strength.

See All Technologies

Advantages of the Cold Chamber Process

Cold chamber die casting offers benefits like reduced corrosion and longer mold life due to the precise control over metal temperature.

Hot Chamber Die Casting Versus Cold Chamber Die Casting

For intricate, large designs demanding strong materials, cold chamber die casting excels with high-melting-point metals. Hot chamber casting prioritizes speed for high-volume production of smaller parts.

Benefits of Aluminum Cold Chamber Die Casting

Aluminum die castings are lightweight and able to withstand the highest operating temperatures of all die cast alloys. One of the most significant benefits is that it creates lighter parts—with more surface finishing options than other die cast metals. Additionally, cast aluminum is versatile, corrosion resistant, retaining high dimensional stability with thin walls and can be used in almost any industry.

BEYOND THE BASICS

Elevate Your Knowledge About Dynacast Cold Chamber Die Casting

Global Reach, Local Expertise

Use our location finder to see which of our global facilities offers the processes and materials you need.

.png&w=268&q=75)