Friction Stir Welding

Dynacast ensures leak-proof, high-strength welding that redefines reliability in manufacturing.

Why Choose

Friction Stir Welding?Friction Stir Welding is the smart choice for projects that demand:- Superior mechanical performance

- Minimizes thermal distortion

- Eliminates defects (porosity, hot cracking, shrinkage)

- Welding of difficult alloys

- Welding of dissimilar metals

- 100% leakproof parts

- Precision assemblies

- Lightweight parts

- Highly durable parts

- Highly repeatable

- Environmentally friendly

- Cost savings

What Is Friction Stir Welding?

Friction stir welding (FSW) is a solid-state manufacturing technology that joins metals without melting, ensuring superior strength and integrity in every weld. By eliminating common defects like porosity, cracking, and distortion, FSW delivers fully leak-proof, high-performance components that meet the demanding requirements of modern applications. Its precision and consistency make it a trusted solution for manufacturers seeking reliability, durability, and efficiency at scale.See Additional Capabilities

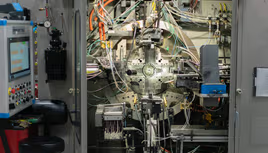

Inside the Friction Stir Welding Process

Friction stir welding joins metals without melting by using a rotating tool to soften and mix the material, forming a defect-free, high-strength bond. This precise method minimises distortion and produces welds that meet or exceed the performance of the base material.

Versatile Material Solutions

FWS enables the joining of advanced alloys once considered unweldable, including high-silicon aluminium, magnesium, and dissimilar metals. This flexibility supports lightweight designs and multi-material assemblies for breakthrough applications. The process combines materials much like "stirring dough," ensuring a seamless metallurgical bond.

Repeatability You Can Rely On

FSW delivers unmatched consistency in high-volume production. With rigid clamping, precise tooling, and seamless CNC integration, Dynacast achieves welds that are repeatable, reliable, and defect-free every time.

Leak-Test Performance Every Time

Unlike traditional fusion welding, FSW eliminates porosity and hot cracking, ensuring 100% leak-proof joints. This makes it ideal for battery trays, cooling plates, and enclosures where fluid-tightness is critical. The process offers long-term durability with superior mechanical and sealing performance.

A Sustainable Manufacturing Choice

FSW eliminates the need for filler materials, shielding glass, and harmful emissions, reducing environmental impact. By lowering energy use and material waste, the process aligns with global sustainability goals. It's a cleaner, greener solution without compromising strength and reliability.

Convert to FSW and Transform Production

By replacing secondary processes like manual assembly, tapping, or brazing, FSW streamlines manufacturing and cuts costs. Companies that adopt FSW benefit from faster cycle times, lower labour needs, and stronger, more durable assemblies.

A Look AtFriction Stir Welding Applications

Friction stir welding applies an advanced process to manufacture a wide variety of high-quality components. Common applications include:

- Cold plates for CPUs, GPUs, and data centre cooling systems

- Battery trays (floor and frame)

- Battery casings

- Battery cooling packs

- PACK tray water cooling

- Drive motor housings

- Housings for electrical control systems

- Heatsinks

- Bearing shields

- Resolvers

- Rotors

- Stators/stator carriers

- Transmission housings

- Centre housings

- Power inverters

- Flange builders

- Vacuum chambers

- Stiffened panels

- Decks for fast ferries

- Floor and lateral structures

- Hydrogen cryogenic tanks

- Space launcher components

- Panels

BEYOND THE BASICS

Elevate Your Knowledge About Dynacast Friction Stir Welding

Global Reach, Local Expertise

Use our location finder to see which of our global facilities offers the processes and materials you need.